Lyophilization, also known as freeze-drying, is a critical process widely used in pharmaceutical manufacturing to preserve and stabilise sensitive materials. This method involves a sophisticated dehydration technique that freezes the product, reduces the surrounding pressure, and removes the ice by sublimation. ‘This process is essential for maintaining the structural integrity and efficacy of pharmaceuticals, particularly those sensitive to heat and moisture, such as vaccines, antibodies, and other biologics. By effectively removing water from the product under low temperatures, lyophilization ensures that the chemical and physical properties of the active ingredients are preserved without compromising their bioactivity.

This article explores the detailed mechanics of lyophilization, its significant advantages, and practical strategies for optimising the process to enhance product stability and extend shelf life in pharmaceutical applications.

Lyophilization Overview: Process, Advantages, and Applications

Lyophilization is a dehydration process that involves freezing the product, reducing pressure, then removing the ice by sublimation (transition from solid to gas). This technique is critical for preserving a wide range of materials, including pharmaceuticals, biopharmaceuticals, and food products, without compromising their chemical structure, potency, or bioactivity.

Advantages:

- Preservation of Material Integrity: By avoiding high temperatures, Lyophilization preserves structural and chemical integrity.

- Extended Shelf Life: Products are stable for extended periods, facilitating easier storage and transportation.

- Enhanced Solubility: Lyophilised products often dissolve more quickly when reconstituted, improving their efficacy.

Applications:

- Pharmaceuticals: Particularly useful for preserving advanced biologics, such as vaccines and antibodies.

- Nutraceuticals: Protects the active ingredients in food supplements.

- Technological Applications: Used in the preservation of heritage objects or other delicate items of biological or organic origin requiring long-term preservation.

The Science Behind Lyophilization: Key Principles and Mechanisms

The science of Lyophilization is based on two primary principles: sublimation and desorption. Initially, the product is frozen rapidly, creating a solid matrix. Then, under vacuum, ice sublimates, leaving behind a porous structure without any liquid phase, which ensures minimal impact on the active ingredients. Finally, residual moisture is removed by desorption under secondary drying conditions to achieve the desired dryness level.

Key Mechanisms Involved

- Freezing: This first step solidifies all the components, preventing migration during drying.

- Primary Drying (Sublimation): Ice crystals evaporate directly to a gas, leaving behind a dry structure.

- Secondary Drying (Desorption): Removes unfrozen water molecules attached to the product molecules.

Detailed Steps in the Lyophilization Process

- Preparation: Before Lyophilization can commence, the product is prepared in a solution or suspension. This preparation ensures that the product is in the appropriate state for freezing, with all components adequately dispersed.

- Freezing: The prepared product is rapidly frozen at very low temperatures. This rapid freezing prevents the formation of large ice crystals, which can damage the product’s structure. The freezing process solidifies all the components, ensuring they remain in place and preventing migration during drying.

- Primary Drying (Sublimation): Under vacuum conditions, the solid ice within the product sublimates into gas. This phase is crucial as it removes the bulk of the water content without passing through a liquid phase, which could lead to degradation or alteration of the sensitive components. The process leaves behind a porous structure, maintaining the physical form of the material.

- Secondary Drying (Desorption): Some water molecules remain bound to the product molecules after sublimation. The secondary drying phase aims to remove this bound water. It involves slightly higher temperatures and can take several hours to days, depending on the product’s nature. This step is vital to ensure the stability and shelf-life of the product, as residual moisture can lead to degradation over time.

- Post-Processing: Once Lyophilization is complete, the dry product can be sealed under a vacuum or in an inert gas environment to protect it from moisture and oxidation. The product is often also further processed into forms that are more convenient for storage, handling, or usage, such as vialing for pharmaceuticals.

Each step in the Lyophilization process is carefully controlled and monitored to ensure optimal results. Parameters such as temperature, pressure, and time are adjusted based on the specific thermal properties and stability requirements of the product.

Strategies for Optimising the Lyophilization Process

Optimising the Lyophilization process involves fine-tuning various parameters to enhance efficiency and product quality.

- Cycle Development: Developing a precise freezing and drying cycle based on the thermal and solute characteristics of the product to ensure stability and efficiency.

- Advanced Technology: Using controlled nucleation to standardise the freezing step can lead to more uniform product quality and faster drying times.

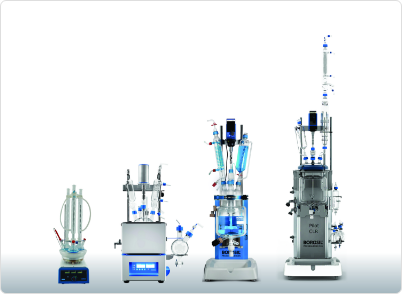

- Equipment Calibration: Regular maintenance, calibration and validation of Lyophilization equipment to ensure consistent performance.

Selecting the Right Vials for Lyophilization

Choosing the right vials for lyophilization is crucial for the success of the freeze-drying process. Consider the following factors to ensure compatibility and performance:

- Material Suitability: Choosing vial materials that are chemically compatible with the drug’s formulation is essential. This prevents interactions that could alter the drug’s properties and ensures the stability of the formulation throughout the lyophilization process.

- Appropriate Size and Shape: Lyophilization vials are designed with specific structural differences to facilitate the freeze-drying process. Unlike standard vials, lyophilization vials typically have a curved bottom. This curvature helps maintain the vial’s stability on surfaces during the freeze-drying cycle, preventing wobbling. It also ensures efficient heat extraction from the formulation, aiding in uniform freezing and drying.

- Compliance with Standards: Always ensure that the vials meet relevant industry standards for pharmaceutical packaging. This ensures the vials maintain the necessary quality and safety guidelines, supporting regulatory approval.

By choosing vials with these key characteristics, you can optimise the lyophilization process, ensuring the integrity of the product and the efficiency of freeze-drying.

Handling and Storage After Freeze-Drying

Handling and storing freeze-dried products correctly after processing is vital to keep their quality intact. Once freeze-drying is complete, the products should be immediately sealed in packaging that protects them from moisture and air. Storage conditions such as temperature and humidity need to be controlled to maintain product stability. For pharmaceuticals, it’s especially important to store medicines as recommended to ensure they remain effective until used. Manufacturers need to provide clear storage and handling instructions to ensure that freeze-dried products retain their intended benefits.

Conclusion

Lyophilization is a sophisticated yet critical process in the pharmaceutical industry, particularly for the stability and preservation of sensitive formulations. By understanding and optimising this process, manufacturers can significantly enhance the quality and efficacy of their products. At Borosil Scientific, we are committed to providing industry-leading solutions that support our clients through every step of their scientific endeavours. Explore our range of products tailored for lyophilization and discover how we can help you enhance your manufacturing processes.