In any regulated lab, whether it’s pharmaceutical, industrial R&D, or water analysis, storage isn’t an afterthought; it’s a procedure. And when it comes to storing chemicals, buffers, and light-sensitive solutions, reagent bottles do the job that most others can’t. However, improper selection can lead to contamination, reduced reagent stability, and non-compliance with regulations.

This article breaks down the types of reagent bottles, their structural differences, application-specific designs, and precise product specs.

Reagent degradation happens through four key factors: exposure to light, air, incorrect sealing, and chemical incompatibility with the container. In high-precision methods, like trace impurity analysis or HPLC, reagent stability is non-negotiable.

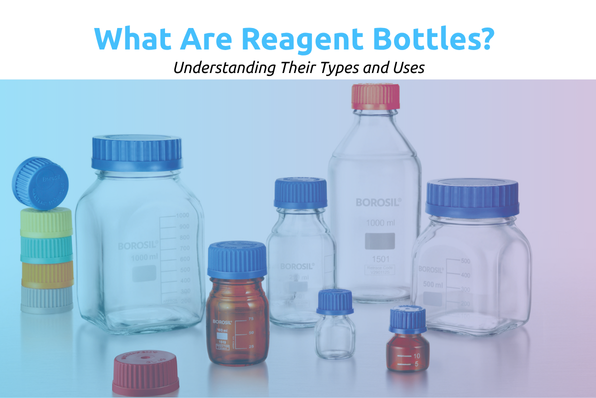

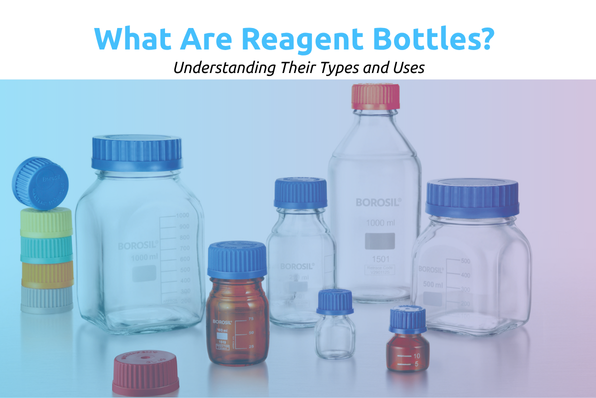

Glass, particularly borosilicate, offers thermal resistance, chemical inertness, and dimensional stability over repeated sterilisation. But the shape, closure system, and colour of the bottle are equally critical.

Bottle design affects both usability and chemical preservation. Narrow-mouth bottles reduce evaporation and are better for pouring liquids. Wide-mouth variants, on the other hand, are designed for solid reagents, viscous materials, or applications needing scooping or spatula use.

| Mouth Type | Best Used For |

| Narrow Mouth | Storage of acids, solvents, light-sensitive materials |

| Wide Mouth | Solid reagents, powders, bulky or high-viscosity solutions |

Choosing the right cap is essential for maintaining chemical integrity. Screw caps are used for routine access. In contrast, glass stoppers are essential when chemical integrity must be maintained over extended periods.

| Closure Type | Material | Best Use Case |

| Screw Cap | PP, autoclavable | Daily-use reagents, frequent access needed |

| Interchangeable Glass | Ground joint borosilicate glass | Long-term storage, acids, minimal exposure needed |

All stoppers from the Borosil Scientific collection are fire-polished for a smooth fit and manufactured under dimensional tolerances that comply with ISO standards.

Borosil Scientific’s model 1506 features a square-shaped, wide-mouth bottle with a screw cap, a design preferred in many quality control labs. Here’s why:

While round bottles (1500, 1519, etc.) offer better hydrostatic strength for vacuum environments, square variants are more ergonomic in high-throughput handling.

| Neck | Closure | Colour | Shape | Key Applications |

| Narrow | Screw Cap | Clear | Round | Every day, solvents and working standard storage |

| Narrow | Screw Cap | Amber | Round | Light-sensitive chemical solutions |

| Narrow | I/C Glass Stopper | Clear | Round | Long-term acid or base storage |

| Narrow | I/C Glass Stopper | Amber | Round | Redox agents, light-sensitive buffer systems |

| Wide | Screw Cap | Clear | Square | Powdered reagents, viscous liquids, media components |

Technicians in controlled environments often utilise multiple reagent types, each with distinct shelf lives, interaction sensitivities, and documentation requirements.

Use Model 1509 – Amber, narrow mouth, I/C stopper. Preserves reagent without light degradation.

Use Model 1501 – Clear, narrow mouth with a PP screw cap. Autoclavable and safe for daily handling.

Use Model 1506 – Square, wide mouth. Allows spooning without spillage.

Each bottle type serves a role. Choosing by shape or colour alone is inadequate.

Improper use of reagent bottles might go unnoticed at first, but the impact on test reliability and sample integrity can be significant. Improper sealing, the use of the wrong cap type, or the incorrect use of a bottle for a reactive chemical can result in poor results or even system-wide contamination. To maintain the integrity of reagents, it’s critical to match the types of reagent bottles to their function, chemical properties, and the lab’s workflow.

| Reagent Type | Recommended Bottle | Reason |

| Volatile organic solvents | Narrow mouth, screw cap | Reduces evaporation and vapour escape |

| Photoreactive compounds | Amber glass, any mouth type | Prevents photodegradation |

| Corrosive acids or bases | Narrow mouth, glass stopper | Ensures a tight seal and prevents chemical interaction |

| Solid chemicals or powders | Wide mouth, screw cap | Allows easy access without contamination risk |

Remember: For long-term chemical stability, Borosil Scientific’s borosilicate glass reagent bottles are the standard in controlled environments.

While polypropylene screw caps are autoclavable and chemically resistant to most reagents, they are unsuitable for reactive substances, such as concentrated acids or peroxides, where glass stoppers are preferred. In such cases, ground joint glass stoppers (available in models such as 1500 and 1509) provide a superior non-reactive seal.

It’s not just about neck size or stopper. Lab workflows vary, and reagent handling must be tailored accordingly. Here’s a functional breakdown to help identify the right fit:

| Type | Best For | Example Use Case |

|---|---|---|

| Narrow mouth, clear | General-purpose liquids not light-sensitive | Buffer solution prep in routine labs |

| Narrow mouth, amber | Light-sensitive chemicals like iodine or nitrate compounds | Redox titration standards |

| I/C glass stoppered | Storage of chemicals that require air-tight, inert closure | Perchloric acid or strong bases |

| Square, wide mouth | Frequent solid transfer, ergonomic handling, and better stacking | Powdered culture media in microbiology labs |

The design of Borosil Scientific’s 1506 square bottle helps reduce the risk of tip-overs while saving shelf space, especially useful in packed storage units or mobile test stations.

While round-bottom bottles remain standard, square bottles are increasingly preferred for their ergonomic and space-saving benefits.

Choosing the right reagent bottle is not a matter of habit or convenience; it’s an integral part of precision work in any regulated lab environment. From the clarity of the glass to the width of the mouth, each feature serves a purpose. Whether you’re storing analytical reagents, preparing titrants, or safeguarding light-sensitive compounds, the wrong choice can compromise purity, reproducibility, and accuracy of results.

Selecting the right reagent bottle should be treated as a critical step in lab setup. Pay attention to chemical compatibility, bottle type, cap system, and photostability needs.

At Borosil Scientific, we understand these lab realities. Our range of reagent bottles, manufactured with precision and certified to meet ISO standards, is available in multiple functional formats. It has been designed to serve real lab professionals with real process control challenges. If you’re setting up a new workflow or re-evaluating your storage systems, our team can help guide the proper selection based on material, reagent compatibility, and frequency of use.