In India, where industrial growth meets urgent environmental responsibility, Effluent Treatment Plants (ETPs) are expected to go beyond basic compliance and actively improve environmental outcomes. Missed readings or untreated discharge can have serious ecological and reputational costs.

Today, the margin for error is thinner than ever. Industrial wastewater treatment is no longer just a compliance mandate; it’s a national priority. Across effluent treatment plants in India, the narrative is moving from ‘compliance under pressure’ to ‘Green Chemistry as practice.’

This shift demands more than mechanical fixes or periodic checks. It calls for science-backed precision. For reliable instrumentation, audit-ready analytics, and tools that turn data into action.

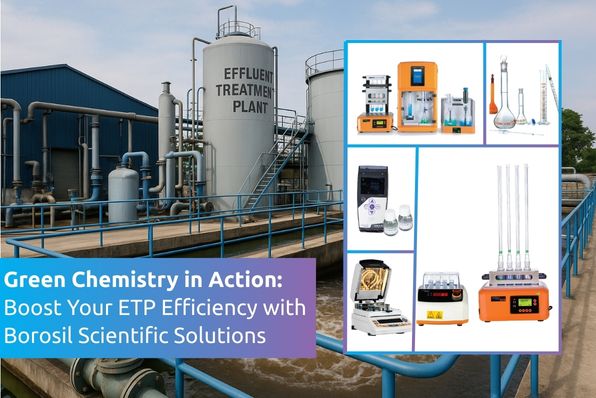

That’s exactly why Borosil Scientific has launched the GreenChem initiative—to make Green Chemistry in industry less of a catchphrase and more of an operating system. To equip ETPs across smart cities, industrial parks, CETPs, and MSMEs with the ability to go beyond baseline compliance and instead become smarter, cleaner, and more future-ready.

Most ETPs are designed with engineering at the forefront—large tanks, optimal flow rates, and pressure differentials. However, what often gets overlooked is the analytical precision needed to validate whether those systems are truly performing. Because it’s one thing to move water through stages and another to know (accurately and in real-time) what’s actually being treated, transformed, or left behind.

Borosil Scientific bridges that gap.

With over six decades of experience in laboratory instrumentation and compliance-grade glassware, we offer a curated portfolio built specifically for industrial water pollution control. And that’s what makes Borosil Scientific’s analytical suite for industrial wastewater treatment solutions so relevant; it’s designed to slot seamlessly into every stage of the ETP process.

The instruments may be compact: meters, incubators, analysers, and sonicators, but their role in treatment efficiency and compliance is multi-dimensional and long-term. These are the tools that make the difference between guesswork and control, between ticking a box and running a future-ready ETP.

No two plants operate the same way. But every plant that takes compliance seriously begins with measuring right.

This stage sets the tone. Knowing what’s entering your plant isn’t just diagnostic; it defines every downstream action.

Borosil Scientific’s pH, EC, and TDS meters allow ETP operators to capture real-time wastewater quality monitoring data before treatment begins. Combined with certified volumetric glassware and magnetic stirrers, these instruments provide reliable sampling and preparation support. This reduces dosing guesswork and enhances treatment predictability for smart city water management and centralised treatment systems.

Electrochemistry meters such as pH, DO, TDS, and EC are essential tools used across all stages of the water treatment process for accurate monitoring and control.

Here, solids settle, oils rise, and the chemical burden becomes visible.

UV-Vis spectrophotometers from Borosil Scientific help quantify COD levels, providing a clear snapshot of the organic burden. For oil and grease estimation, our qualitative and quantitative filter papers, along with glassware, support precise gravimetric analysis. To separate suspended solids and prepare clear samples, a combination of BOROPure Nylon-66 Membranes, the Glass Micro-Filtration Assembly, and the Stainless Steel Filtration Manifold enables multi-stage separation with reliability and consistency.

This level of resolution is critical, not just for treatment efficiency but for audit readiness. Because knowing where you started helps justify where you end up.

This stage focuses on the biological breakdown of organic matter, where microbial activity plays a central role in reducing pollutant load.

DO meters from Borosil Scientific help maintain the optimal oxygen levels for aerobic digestion. Kjeldahl nitrogen analysis systems provide accurate nitrogen analysis to assess nutrient levels and monitor process consistency.

Combined, these instruments allow operators to spot inefficiencies before they compound and to prevent secondary stages from becoming compliance bottlenecks.

Even after biological treatment, residual contaminants like nutrients, colour, and conductivity imbalances often remain. This is where final-stage validation becomes non-negotiable. This step is like a final checkpoint. If something fails here, it’s safe to assume that everything upstream is compromised.

Borosil Scientific’s instruments support this process with UV-Vis spectrophotometers for monitoring nitrates, phosphates, and colour levels; COD analysers to verify chemical load removal; and pH/EC meters to confirm discharge quality and help achieve goals like Zero Liquid Discharge (ZLD) in India. For workflows that require stable temperatures, such as COD digestion or UV-Vis analysis, recirculating chillers provide consistent, low-noise cooling.

At this stage, the goal is not exploration; it’s confirmation that treated water meets the required discharge standards.

Often ignored, sludge carries its own regulatory load. Whether the goal is composting or compliant disposal, it must be measured, logged, and characterised.

Kjeldahl systems and electrochemistry meters assess nitrogen potential and pH levels, while moisture analysers ensure accurate measurement of sludge dryness. This is very important for handling, transport and reuse of sludge. Ultrasonic bath sonicators enable deeper disintegration analysis when needed. Every insight here strengthens your data trail, ensuring alignment with environmental monitoring equipment standards and reporting norms.

Across every stage of effluent treatment—whether you’re sampling influent, monitoring secondary breakdown, validating final discharge, or managing sludge—some laboratory essentials from Borosil Scientific quietly keep your operations on track.

Our Patented Bottle Top Dispensers, trusted for precise and safe reagent dispensing, reduce errors during sample prep and titration. Volumetric glassware, a Borosil Scientific hallmark for decades, ensures accuracy in every measurement, dilution, and transfer. Heating mantles and water baths provide consistent thermal control for digestion and incubation workflows, while glassware dryers help maintain glassware integrity between cycles in high-throughput labs.

BTD, glassware dryer, heating mantles, volumetric glassware [understand where these four products come in and in which stage, if they are relevant in all stages, then add a paragraph about general utilities throughout the process after sludge treatment]

These everyday lab utilities aren’t just accessories—they’re the backbone that keeps your ETP analytics reliable, repeatable, and always ready for inspection.

You partner with Borosil Scientific because every product comes with something deeper: a legacy of 60+ years, ISO 9001 standards, and a commitment to help you solve, not just measure.

You get:

Whether you’re a CETP operator, an EHS head in a pharma plant, or an MSME chasing ZLD, Borosil Scientific’s portfolio is engineered to scale with your needs without breaking your budget or your audit trail.

From Swachh Bharat to Jal Shakti, from Smart Cities to NAPCC—Borosil Scientific’s Green Chemistry Initiative isn’t riding the wave. It’s helping shape it. We’re doing it by putting Green Chemistry in the industry into action right where it matters most: inside your effluent treatment plant.

At its core, GreenChem isn’t just a campaign. It’s a shift in mindset. For ETPs looking to modernise without compromise, it’s a movement worth joining. You don’t need to overhaul your plant. You just need to upgrade the insight behind it.

With Borosil Scientific’s wastewater testing instruments, environmental compliance tools, and wastewater treatment solutions, industrial water pollution control becomes less about firefighting and more about foresight. It’s a shift from reactive fixes to measured, accountable operations that hold up under scrutiny.

When your process stays consistent, your plant avoids interruptions. And in effluent treatment, that kind of stability speaks for itself.