Stainless Steel Filtration Assembly

Key Components of Stainless Steel Filtration Assembly

Every stainless steel filtration unit is engineered to reduce reactivity, improve throughput, and withstand repeated autoclaving.

|

Component |

Material |

Specification |

|

Funnel |

SS316 |

Spin-lock or External Clamp, 300 ml / 500 ml / 1L |

|

Membrane Support Screen |

SS316L |

47 mm, High solvent compatibility |

|

Support Base |

SS316 |

With silicone stopper, Size #8 / Stainless Steel Filter#10 |

|

Lid |

Silicone |

Autoclavable, contamination resistant |

|

Valves (in manifold) |

PTFE |

Individual flow control |

|

Vacuum Source |

Diaphragm Pump |

Oil-free, -670 mm Hg |

Each part is built to operate under high solvent exposure and repetitive sterilisation. The support screens are designed to get even membrane contact and consistent flow, with no interference from the metal surface.

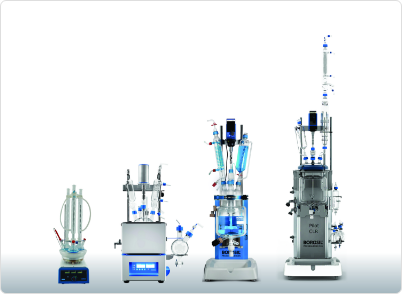

Stainless Steel Filter Funnel: Borosil Scientific’s 47 mm stainless steel filter funnels, made from SS316 and SS316L, are available in spin-lock and external clamp types. They include a silicone stopper (Size #8 or #10 for 1L), support base, and are fully autoclavable—ideal for solvents incompatible with glass.

Stainless Steel Filtration Manifold: This manifold is used for multi-sample setups and is fabricated from SS316 with PTFE valves. It is compatible with all Borosil Scientific stainless steel filter funnels. 100% autoclavable and ideal for simultaneous filtration with independent control per stage. Often used for microbial or particulate testing.

Sterility Testing Manifold with Inbuilt Pump: Each stage includes its own oil-free vacuum pump, eliminating external lines. Made entirely of SS316, this manifold is compatible with stainless steel, reusable PP, and disposable sterile PP funnels through adaptors. Suitable for GMP setups and microbial testing workflows.

Oil-Free Diaphragm Vacuum Pump: Achieving a vacuum level of -670 mm Hg, this diaphragm-based pump is suitable for both aqueous and organic solvent filtration. Operates without oil to minimise maintenance and contamination risk. Integrates easily with Borosil Scientific’s manifold and funnel systems.

SS Filtration Assemblies vs. Other Filtration Materials

Borosil Scientific uses only SS316/SS316L for superior corrosion resistance, thermal tolerance, and stability. Ideal for HPLC solvents and sensitive buffers, these assemblies ensure fewer breakages, easy cleaning, and long-term use. Compatible with both reusable and disposable funnels, they offer unmatched reliability, essential for high-throughput, regulated labs where consistency and minimal downtime are critical.

Comparison of filtration media by suitability:

|

Feature |

Stainless Steel (SS316) |

Glass |

|

Chemical Resistance |

Excellent |

Moderate |

|

Mechanical Strength |

High |

Fragile |

|

Autoclavability |

100% |

Yes |

|

Reusability |

Very High |

Moderate |

|

Maintenance |

Easy |

Delicate |

SS316 components are preferred in high-solvent filtration or buffer clarification where repeatable sterilisation is needed. Borosil Scientific exclusively manufactures tubular filtration systems using these specifications.

How to Choose the Right Stainless Steel Filtration Assembly?

Selecting the right assembly depends on your application and material requirements. Use these points to match lab needs with suitable Borosil Scientific components.

-

Assess chemical compatibility: SS316 funnels and SS316L screens are particularly suited for HPLC solvents and buffer solutions due to their resistance to corrosion and leaching.

-

Match funnel volume to throughput: Use 300 mL for small batches; 1 L for routine filtration. All Borosil Scientific funnel variants are available in both spin-lock and external clamp formats.

-

Choose based on sterility needs: Choose multi-stage manifolds with built-in vacuum to reduce contamination and enable parallel runs.

-

Consider funnel flexibility: Borosil Scientific assemblies accommodate stainless steel, reusable PP, and disposable sterile PP funnels with adaptor options. This adaptability simplifies workflow transitions without needing separate equipment.

-

Integrate compatible vacuum systems: The oil-free diaphragm vacuum pump by Borosil Scientific maintains steady suction and minimal maintenance.

-

Ensure autoclave readiness: All units are 100% autoclavable, supporting sterilisation cycles standard in GMP and ISO-regulated environments.

Stainless steel filtration assemblies use vacuum to pull liquids through membranes. Borosil Scientific’s modular, autoclavable units ensure precise, sterile filtration with stainless steel components and PTFE valves.

Borosil Scientific filtration assemblies last several years with proper care. SS316/SS316L construction ensures durability against solvents, sterilisation, and repeated use in demanding lab conditions.

Yes, Borosil SS filtration assemblies are cost-effective long term. Their durable, autoclavable design lowers replacement needs, reduces inventory, and cuts downtime in high-throughput labs.

SS filtration assemblies are designed for vacuum-based liquid filtration. They are not recommended for gas-phase use, as components are not rated for gas pressure conditions.

SS filtration assemblies are suited for vacuum-based filtration up to -670 mm Hg. They are not designed for high-pressure applications requiring PSI-rated systems.