When it comes to extracting lipids or specific components from solid matrices in a lab environment, few methods offer the robustness and efficiency of the Soxhlet extraction process. Introduced in 1879 by Franz von Soxhlet, this technique remains widely used in the food and feed industries for quantitative extraction, particularly for determining the total fat content in samples such as seeds, feed, and food.

Despite the availability of faster or automated alternatives, Soxhlet extraction remains the benchmark in many analytical protocols due to its accuracy, reproducibility, and solvent efficiency. This post covers the principles, apparatus, procedure, and optimisation of Soxhlet extraction, along with an examination of modern features that enhance the classic method’s safety and efficiency.

The Soxhlet extraction process is a continuous solvent extraction technique used when the compound of interest has limited solubility in a solvent and is embedded in a solid matrix. The system uses a reflux-based mechanism to repeatedly wash the sample with fresh portions of solvent, extracting soluble compounds over multiple cycles.

The Soxhlet apparatus typically consists of:

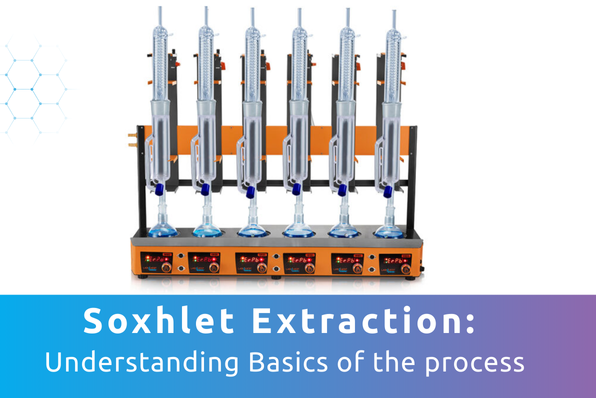

In modern laboratories, the Soxhlet apparatus has evolved from basic glassware setups into systems with interchangeable joints, modular glass parts, and enhanced cooling systems. For instance, using a condenser with bulbous structures, such as the Soxhlet apparatus from Borosil Scientific, significantly increases surface area and improves cooling capacity compared to a straight Liebig condenser.

Here’s how the procedure typically unfolds in a laboratory setting:

The efficiency of this system depends on PID control, solvent compatibility, and uninterrupted reflux cycles.

Despite its precision, classical Soxhlet systems have limitations. These include:

However, recent updates to Soxhlet heating units and holders have addressed many of these issues.

Even with newer technologies available, Soxhlet holds its own because of several built-in advantages:

Especially in fat estimation, it remains a preferred method due to its ability to isolate total extractable lipid content without solvent degradation.

The Soxhlet extraction process finds applications in various industries due to its accuracy in isolating total extractables:

Fat estimation in oilseeds and animal feed is still largely carried out using Soxhlet-based systems. The method ensures complete lipid extraction, including both bound and free fats, which is necessary for nutrition labelling and feed quality assessment.

Solvent choice depends entirely on the nature of the analysis. The following table summarises common pairings:

| Target Compound | Recommended Solvent |

| Fats and Oils | Petroleum Ether, Hexane |

| Polar Plant Extracts | Ethanol, Methanol |

| Hydrophobic Organics | Dichloromethane, Toluene |

| Non-polar Pesticides | Acetone: Hexane (1:1) |

Modern Soxhlet apparatus with versatile joint design supports safe use of aggressive solvents. Borosil Scientific’s glassware range ensures chemical resistance and durability across extraction solvents.

Compared to newer technologies such as supercritical CO₂ extraction or microwave-assisted extraction, the Soxhlet method is slower. However, where absolute recovery matters more than speed, Soxhlet remains unmatched.

| Parameter | Soxhlet | Microwave-Assisted | Supercritical CO₂ |

| Reproducibility | High | Medium | Medium |

| Solvent Flexibility | Wide Range | Limited | Specific to CO₂ |

| Throughput (per batch) | 1–6 Samples | 1–2 Samples | Variable |

| Operator Training Needed | Low | Moderate | High |

For routine labs, the cost-benefit balance still favours Soxhlet, especially when paired with 6-zone heating platforms and digital safety features that allow unattended operation.

To ensure consistent performance:

It’s advisable to conduct a calibration check for temperature zones at least once every six months, especially if using digitally controlled Soxhlet units.

Here are some practical tips for error-free extractions:

For laboratories that prioritise analytical depth, standardisation, and affordability, Soxhlet extraction remains indispensable. It’s one of the few techniques that can deliver complete recovery without needing exotic instrumentation or heavy calibration. When paired with quality apparatus and a controlled heating system, it becomes a reliable pillar in food and feed analysis.

At Borosil Scientific, we continue to enhance this legacy with digitally optimised Soxhlet assemblies designed for modern labs. Whether you’re setting up a fat estimation station or standardising plant extract protocols, our Soxhlet extraction solutions offer both performance and peace of mind.

Looking for compliant, high-precision Soxhlet systems? Reach out to our team or explore our product documentation to find the correct configuration for your lab.